THERMAL

Heat Pipes & Vapor Chamber / Integrated Vapor Chamber Heat Sinks BACK

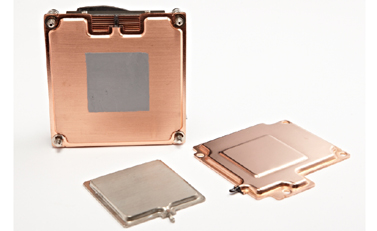

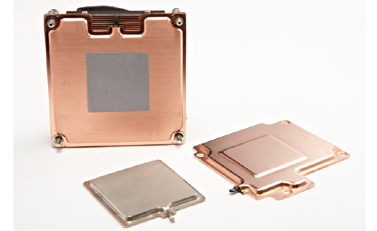

Integrated Vapor Chamber Heat Sinks

Integrated Vapor Chamber Heat Sinks

A vapor chamber is a high-end thermal management device that can rapidly spread heat from a small source to a large platform of area. A properly designed vapor chamber with heat sink can improve the thermal performance by 10- 30% over copper, and heat pipe based solutions. A vapor chamber is much lighter than solid copper, due to its internal chamber structure. In many cases, a vapor chamber based heat sink weighs the same as an extruded aluminum heat sink, but works much better than a copper heat sink.

Design Guidelines

Design Guidelines Vapor Chamber Design Guidelines,

-Size : 400x400 mm (maximum)

-Thickness: 3.0 mm (minimum)

-Shape limitation : Base on stamping technology

-Heat Source : ≧ 15x15 mm

-Q-max : ≦ 150W

-Force Loading : ≦60 lb

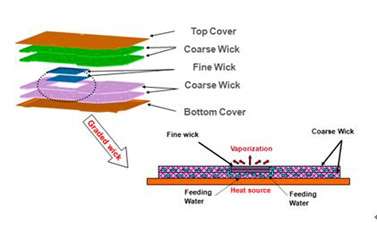

Vapor Chamber Structure

Vapor Chamber StructureA vapor chamber consists of a sealed vacuum vessel, with an internal wicking structure, and a small amount of working fluid. Rego’s Vapor Chamber is multi-layered copper mesh wick bonded. Mesh wick structure is similar to sinter powder wick structure but with better pore size uniformity. Compound Multi-layer Mesh Wick performs better than simplex sinter wick structure.

Quality Assurance

Quality AssuranceRego’s vapor chambers are very reliable thermal devices. They are well tested in production line according to the following tests,

-100% Helium leakage test

-Water Quality Inspection, on line detecting.

-100% Weight filling quantity

-100% Thermal aging

-100% Thermal Performance test